CNC machine tool is the product of the combination of information technology and mechanical manufacturing technology, which represents the technical level and development trend of modern basic machinery. In recent years, China's CNC machine tool industry has developed rapidly, and there are nearly 100 CNC machine tool manufacturers. In order to speed up the development of China's CNC machine tool industry and better meet the needs of national economic development.

CNC machine tool is the product of the combination of information technology and mechanical manufacturing technology, which represents the technical level and development trend of modern basic machinery. In recent years, China's CNC machine tool industry has developed rapidly, and there are nearly 100 CNC machine tool manufacturers. In order to speed up the development of China's CNC machine tool industry and better meet the needs of national economic development, the State Planning Commission and the Ministry of Machinery Industry have listed important basic machinery as one of the four key areas for revitalization in the "outline for the revitalization of the machinery industry", and the important basic machinery is mainly to develop CNC machine tools. During the "Ninth Five-Year Plan" and before 2010, the development policy of my country's CNC machine tools is: focus on six types of mainframes (CNC lathes, machining centers, CNC grinders, CNC forging and pressing machine tools, CNC heavy-duty machine tools and CNC precision electrical machining machine tools), and focus on breaking through CNC systems; Develop popular models and improve reliability; Combine internal and external, and focus on me to realize the industrialization of my country's data control machine tools. During the "Ninth Five-Year Plan" period, emphasis will be placed on improving reliability, increasing varieties, and popularizing CNC systems and CNC machine tools to achieve economic scale production. By 2000, the variety of CNC machine tools had developed to 1000, of which 100 reached the international level in the early 1990 s. The average trouble-free time of CNC machine tools and CNC systems reaches 10000 hours, and the annual output reaches 20000 units. Popular products are basically based in China.

At present, all manufacturing enterprises in the machine tool industry are changing their concepts, raising awareness, starting from the needs of users, increasing varieties, improving quality, reducing costs, and strengthening after-sales service to better meet the needs of users. At the same time also sincerely hope that the majority of users more choose domestic CNC machine tools, and more valuable advice.

CNC machine tools have the following obvious characteristics:

1) Suitable for the processing of complex special-shaped parts.

2) Realize computer control and eliminate human error.

3) Accuracy compensation and optimal control can be realized through computer software.

4) Machining centers, turning centers, grinding centers, electrical machining centers, etc. have tool magazine and tool change functions, which reduces the number of clamping and improves the machining accuracy.

5) CNC machine tools to increase the characteristics of flexible machining equipment. Flexible processing is not only suitable for many varieties, small and medium batch production is also suitable for mass production, and can alternately complete the processing of two or more different parts, increase the function of automatic transformation of the workpiece, can achieve unattended operation at night. A flexible manufacturing system (FMS) consisting of several CNC machines (machining centers) is a more flexible automated manufacturing system, including processing, assembly and inspection.

CNC machine tools can be divided into three levels:

1) high-grade CNC machine tools: refers to the processing of complex shapes of multi-axis control or process concentration, high degree of automation, highly flexible CNC machine tools.

2) Universal CNC machine tools: with man-machine dialogue function, wide application, moderate price, usually called full-function CNC machine tools.

3) Economical CNC machine tools: simple structure, medium precision, but cheap, can only meet the general accuracy requirements of processing, can process relatively simple shapes of straight lines, oblique lines, arcs and threaded parts.

The principles to be followed in the selection of CNC machine tools are:

1) Practicality: It refers to the clear CNC machine tool to solve which one or several problems in production.

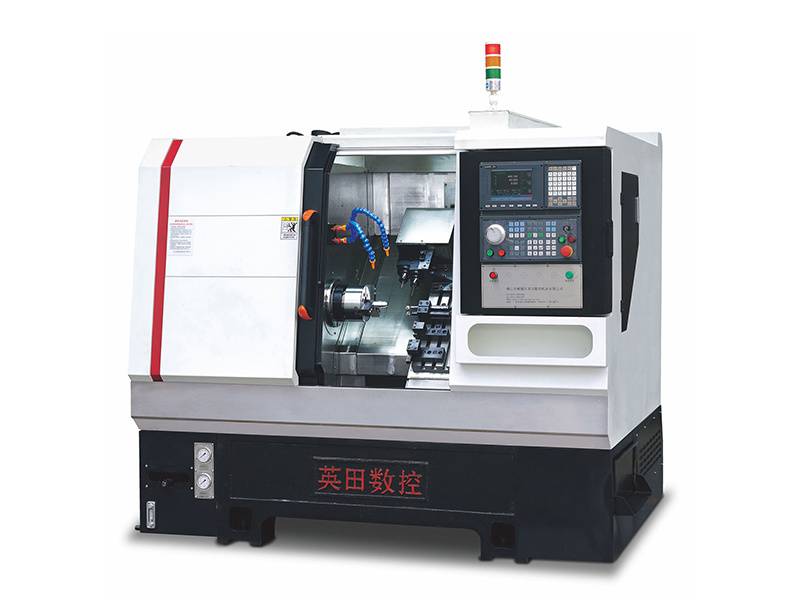

Foshan Shunde Yingtian CNC Machine Tool Co., Ltd., founded in 2007, Guangdong high-tech enterprises, products through the IS09001-2005 international quality management system certification. It is a professional manufacturer specializing in CNC CNC lathes, turning and milling composite lathes, turret lathes, turret tailstock lathes, double-spindle lathes and lathe whole line automation production equipment. It has R & D engineers and industry application engineers who have been engaged in CNC lathes for more than ten years. It has advanced and mature production technology and process and a complete after-sales service system. The company has a number of inventions and practical patents.

The company adheres to the principles of excellence, quality first, and customer service. After more than ten years of accumulation, it has accumulated rich production management, processing technology, and tooling in industries such as automobiles, construction machinery, motorcycle accessories, home appliances, lighting, medical devices, and electronic communications. Fixture design, automated production supporting experience. To provide you with a complete precision parts processing technology production solutions, improve the overall technical solutions.

Ten years of business, a hundred years of tree brand, service is the survival of machinery enterprises, from the factory production enterprises to the factory service-oriented enterprises, to build service-oriented machinery manufacturers. To provide customers with high quality and complete after-sales service system.